Programmable Logic Controllers (PLC)

Programmable logic controllers (PLCs) are technical devices used to automate technological processes. This is a specialized electronic device in industrial design, operating in real time conditions.

The PLC can be digitally programmed and thus very easy to adapt to the requirements of a specific process. The main mode of operation of the PLC is its long-term autonomous use, often in adverse environmental conditions, without serious maintenance and without human intervention.

The PLC is the ideal solution for individual digital control of various applications, machines, systems and processes.

NS series PLC

PLC series NS manufactured by Nova Solutions are serial, inexpensive, flexible and versatile tool for creating process automation systems of any complexity in the oil and gas, power and other industries.

The NS series PLCs are based on a modern electronic components base, provide the ability to process a large amount of information with minimal time. As well as high reliability of automated process control systems due to the support of a distributed structure, redundancy and replacement of modules in hot-swap mode.

PLC NS-50

The NS-50 controller is designed to collect and process information from primary sensors, generate control signals according to specified algorithms, receive and transmit information via various communication channels. It is used to build local automation systems for technological processes.

The key features of the NS-50 controller are:

- low-channel I/O modules (1…16 channels) 12 mm wide;

- scalability with discreteness in one module;

- "hot-swap" replacement of controller input/output modules;

- runtime environment supporting 5 IEC 61131-3 languages;

- installation on a standard DIN-rail 35 mm wide.

The controller includes the following types of modules:

- PLC power supply;

- central processor;

- interface;

- communication processor;

- analog input;

- analog output;

- discrete input;

- discrete output;

- impulse counts.

The NS-50 controller has a block-modular design, consisting of one or more crates, which include various types of removable modules mounted on a DIN rail. The module is the main element of the controller and, depending on the type, performs a particular function.

The selection of the required configuration of controller modules in accordance with your needs and depending on the tasks is carried out by the company's specialists. You can leave a request through the feedback form.

PLC NS-001

Functional capabilities:

- support for redundant power supplies for the internal PLC bus;

- high-speed internal data bus (for communication between crates);

- modular crate - possibility of crate expansion with one module discreteness, mounting on a 35 mm height DIN rail;

- remote input/output stations connection to the central processor using the ring, star, or bus topology;

- 0.5GB non-volatile memory for user archives;

- programming environment with all IEC 61131-3 standard languages support, as well as CFC.

Purpose:

- Local automation systems for industrial and administrative facilities;

- Geographically distributed telemetry systems, dispatching systems.

Technical specifications:

Minimum application program cycle time

Time synchronization accuracy

Input supply voltage range

Operating temperature range

10ms

Up to 50 µs

18…36 V DC

–40 … +60°C

Communication capabilities:

Supported exchange protocols:

- HART v6, v7;

- IEC 60870-5-101 (Master / Slave);

- IEC 60870-5-104 (Master / Slave);

- Modbus RTU (Master / Slave);

- Modbus ТСР (Master / Slave, With expansion capabilities);

- OPC DA, OPC UA;

- FTP, SNMP v3, SysLog;

- Possibility to implement additional exchange protocols according to customer requirements, including non-standard.

Interface support:

- USB host 2.0;

- RS-232 / RS-485;

- Ethernet 100 Мбит/с RJ-45 (full duplex) — up to 4 ports per CPU;

- Ethernet 100 Мбит/с FO (Single-mode, Multi-mode) — up to 2 ports per CPU.

NS-001 CONTROLLER MODULES:

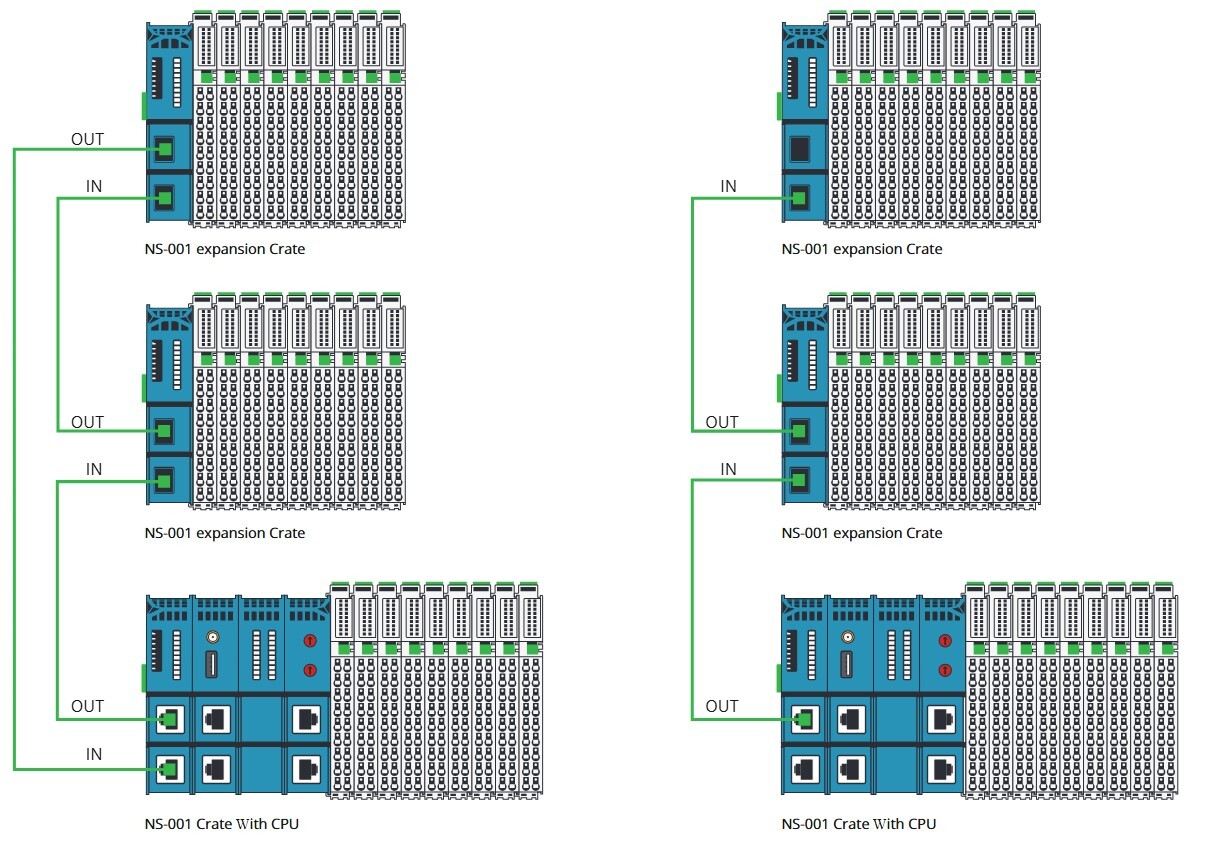

NS-001 PLC HARDWARE CONFIGURATION

support for remote expansion crates

possibility of separating crates

at a distance of up to 10 km

(via fiber-optic communication line)

at a distance of up to 10 km

(via fiber-optic communication line)

Fig. 1. NS-001 PLC connection examples

Hisoblash uchun ariza yuboring